Folks,

A lot has been happening at EastBridge since our last update. While we can usually count on August being a sleepy month, at least for the initiation of new projects, we didn’t experience any slowdown. Our team has been very busy with a diverse group of exciting hardware projects. I’ve summarized a few of them below.

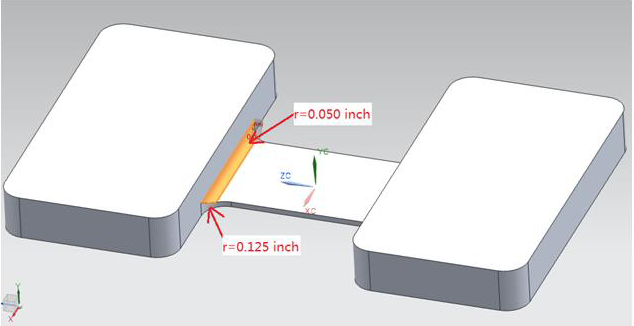

Part Update: Strain Gauge Body

Last month I wrote about a RFQ that we received for a Strain Gauge Body with a few ambiguous requirements shown in the drawing. We weren’t sure if the radius on the “neck” needed to exhibit the 32 microinch surface finish called out for the gauging surface (please see the image below).

As I’ve mentioned before, while common sense indicated that the radii didn’t require the same smooth surface as the other areas, we weren’t sure. As we want to get it right (and common sense is in short supply nowadays) we asked. We were right, the project moved forward and our customer is happy.

Product: Therapeutic Bidet Seat

We were approached by a team of industrial designers and product developers with a urgent project. They needed to (very) quickly design, build models and prototypes and test a new aftermarket Therapeutic Bidet Seat for disabled and elderly users. They were tasked with generating a brand new, “ground up” design and needed to get the job done in three months time.

It was determined that the large injection molded plastic components and final assembly will take place in the USA. The other parts and sub-assemblies were to be sourced from a corps of global vendors that could provide the best “QVR” (quality-value ratio).

The design team asked us to develop a rapid response “BOM Builder” team to develop redundant sources of membrane (Kapton) flexible heaters, micro servo motors, diaphragm & gear pumps, heated blowers, water heaters, three and four way valves, PCBs and many other parts.

The EastBridge team carried out the research and identified sources of supply in China, Korea, the Czech Republic, Taiwan and the USA. They interviewed the candidate vendors, obtained and reviewed product literature and then purchased representative samples of each item. Our engineers then performed a tear down and characterization of the parts to assess their build quality, reliability and confirmed the international certifications.

The next step involved narrowing the field to principal and secondary vendors for each class of product and visiting each (if we hadn’t been there before) to execute our on-site manufacturing capability & quality systems audit.

Thus far, we’ve qualified eighteen vendors for the program, have procured pre-production quantities of each item to support the prototype build and are preparing to customize the parts where necessary.

We shine the brightest when the products specified by our customers require on-the-fly engineering and customization.

Program: Quality Backstop Plan

Sometimes our clients are sourcing from vendors that EastBridge didn’t identify. They ask us to provide a range of back-end services at these factories. Sometimes, when something goes very wrong, our work falls into the “backstop” category.

A recent example of this backstopping is the work we did for a “book plus” client. Book Plus is a segment within the publishing industry where books are packaged with accessories such as DVDs, hobby kits, toys, etc.

In the case of this project (please see the attached photos) the printed PVC play mat packaged with a children’s book was found to contain an enormous amount of lead. [Please note that EastBridge did not identify, qualify or manage the vendor.] Once the discrepant mats were discovered, the end user engaged EastBridge to remove from retail packaging, segregate and destroy the discrepant mats, coordinate the production of replacement mats and supervise the insertion and repacking of the product. Our colleague Hill Miao, senior quality engineer (the gentlemen with the light blue shirt and graying crew cut) is shown supervising the effort.

We utilized our network of vendors, laboratories and logistics resources to turn the order in three days and ship the order on time. We also guaranteed the compliance of the new mats, inspected the finished product and assured chain-of-custody for the defective mats.

If you’re ever in need of similar services, I’ll be pleased to discuss the scope of the project and our experience.

So, lot’s happening. I’ll update all of you next month with a fresh round of Parts, Products & Programs.

Cheers,

Jack Daniels

+1.617.285.2486