EastBridge Strategic Sourcing: Parts, Products and Programs

February 2019

Folks,

I hope that you’re all keeping busy – I know that we are. I’d also like to wish a healthy and prosperous Lunar New Year to our friends, clients and suppliers around the world who celebrate the holiday.

Part: Lithium Ion “Pouch” Batteries

We’re working on a new electronic product in the consumer health care space. The finished product contains a rechargeable lithium ion “pouch” battery. Contained in a flexible-laminated aluminum-polymer composite skin, pouch batteries are generally customized to fit into enclosures and are conformable to fit into tight places. They’ve become common in handheld and portable electronics and we all rely on them.

The ubiquity of pouch batteries sometimes makes us overlook their importance and the risks associated their use. We’ve learned that “a battery isn’t just a battery”. They’re not a low risk generic product (think sheet metal screws). There’s a broad range of features, life cycle and quality associated with each vendor, brand and part number.

Because of these factors, plus the scrutiny of domestic & international certifying agencies such as CPSC, REACH and UL, we insist of going the extra step of “going upstream” to understand the pedigree of the batteries used in the products that we’re building.

I’m glad that we do… Please see the results of a recent low temperature cycle/short circuit stress test we completed recently.

The batteries failed dramatically, exhibiting blistered and split skins, smoke and dead shorts. Needless to say, we’ve disqualified the supplier and instructed the CM to purchase batteries from one of our qualified suppliers.

Product: Aluminum-Magnesium Shell Luggage

Staying with the theme of product life cycle testing, we’re currently working on an integrated line of luggage. The product family includes aluminum-magnesium shell, poly carbonate and soft designs.

One aspect of the product development process involves testing the new products to confirm that they’ll meet the customers’ requirements. We break this down into the development of testing protocols for many of the components and sub assemblies.

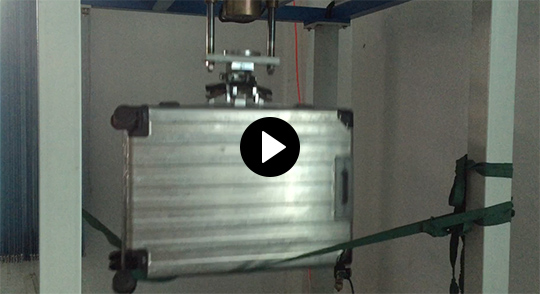

While not as high risk as batteries, you certainly don’t want the baggage handler to pull the handle off of your new suitcase. In the video below, you can see the “advanced aging” test developed to stress the new handle design.

The suitcase is over-weighted, attached to an automated test fixture and repeatedly “jerked” in an effort to make the handle fail. Torturous, but best to make the handle fail while in development at the factory and not on the baggage carousel.

Program: Backpack Concept Development

We transition hundreds of new products into manufacturing every year. Some are simple, others enormously complex. All come with complications – the path to the finish line is rarely straight.

We’re now developing a new backpack for a medical device customer. While the product looks straightforward, the interaction of the design elements, product performance in the field, material properties and manufacturing techniques makes this a challenging program.

We’re strong advocates of walking before running… In the NPI business, that directs us to first build models, then prototypes and eventually pre-production units.

Models can be “looks-like” or “looks-like/works-like” and are built in the model shop. Prototypes are usually “looks-like/works-like” and are usually built on the engineer’s desk, not on the shop floor. Once the designs are validated, we move onto the shop floor and build pre-production units, using volume manufacturing techniques and tooling.

Pictured above are the looks-like paper model next to the looks-like/works-like fabric prototype. We think this shows the trajectory of the concept development process and a visual example of “looking before you leap”.

Cheers,

Jack Daniels

+1.617.285.2486