Folks,

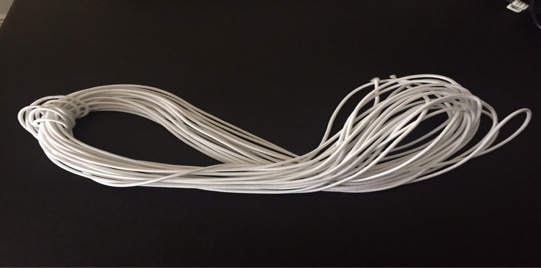

Please take look at the photograph below. It shows a sample of an elastic cord with a “lamb knitted” polyester and Spandex cover. Our customer asked us to develop a supply of the cord and then fabricate small loops that are incorporated into a “single use” or disposable medical device.

Looks simple, right? How complicated can it be to develop some stretchy cord? Well… Pretty darn complicated.

While our customer provided a drawing that defined the basics such as the cord diameter, length and elongation (50%), other elements such as color (white, exactly how white, which white?), basis weight (grams/meter), Young’s modulus (the amount of force required to stretch the cord over a fixed distance) and the composition and style of the knitted cover (the number of textile stitches per inch or the density of the knitted yarns) weren’t called out.

When we pressed our customer, they said “we want it exactly like we’re getting it now”.

We face this situation every day. Our customer knows what he or she wants (“make it so it works in my device”) however the details aren’t clearly or completely stated. There’s a specification, but it’s not written anywhere. Rather it’s more implied or coded into a model, a prototype or the designer’s head.

We sometimes receive a drawing, a product requirements document (PRD) and if we’re fortunate, a sample. Those elements along with our discussions with the customer help us to tease out a specification that allows us to define the product. But it’s not a straight path to the goal line.

In the case of the elastic cord, we were able to draft a PRD that minimized the ambiguity and defined the intangibles around two key properties. The “feel” or “hand” for the knitted cover was very important to the users as well as the “snap back” or Young’s modulus. In order to do this, we needed to build four generations of cord samples, supplied by two vendors, fabricate loops and build them into finished products that were evaluated by the product management team.

The take away from this is that products that are uncomplicated in appearance aren’t necessarily simple once you get under the skin. When you’re going out to generate a quotation and develop a supplier, the investment in time to pin down as many variables as possible will pay dividends.

Cheers,

Jack Daniels

+1.617.285.2486